威达机械

集研发、设计、生产、销售一站式服务

One stop service for research and development, design, production, and sales 在线咨询 >

quick response

Free customization

Worry free service

PRODUCT DETAILS

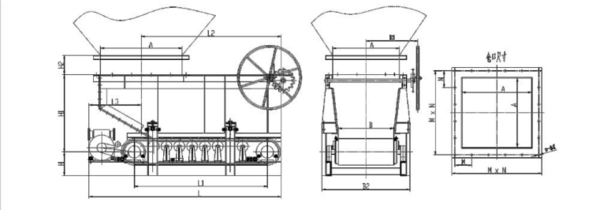

Product Introduction

Chain belt feeder is a new type of feeding equipment developed on the basis of reciprocating feeder, which overcomes the drawbacks of intermittent feeding of reciprocating feeder and achieves continuous and adjustable feeding amount. Can be replaced with the widely used reciprocating feeders nowadays. According to the different material characteristics, this equipment can be divided into belt type and chain type, and can also be made into extended types according to customer needs. Meanwhile, according to the requirements of the conveying process, a horizontal or inclined conveying system can be synthesized from a single or multiple units, which can be used for horizontal or inclined conveying.

Working principle

The material in the silo enters the guide groove through the connecting section and falls onto the steel wire tape. When the tape is stationary, the material stops moving due to internal friction, forming a static accumulation at a certain angle at the discharge port; When the driving drum starts to rotate under the drive of external power, it drives the tape to move, and the tape drives the material on it to guide to the discharge port. The running tape turns back after unloading at the discharge port, and the material is continuously discharged from the discharge port, thus completing the feeding process; The secondary sealing device provides sealing for materials leaking from the gap between the guide groove and the tape; Changing the feeding amount can be achieved by adjusting the speed control handwheel of the planetary friction type continuously variable transmission of the rotating arm to change the output shaft speed and the size (height) of the tape running speed, thereby changing the feeding amount; Changing the feeding amount can also be achieved by selecting a frequency converter and adjusting the motor speed to change the feeding amount. During the operation of the belt coal feeder, the main load of the system is supported by rolling bearings, resulting in low operating resistance, low required driving power for the equipment, and long working life of all system components.

Application scope

At present, the commonly used belt widths for belt conveyors are: 500/650/800/1000/1200/1400/1600/1800/2000/2200/2400mm.

Used in various industries such as metallurgy, mining, coal, ports, power stations, building materials, chemical industry, light industry, petroleum, etc.

The material can be transported by a single or multi machine combined transportation system, which can transport bulk materials, as well as various small weight items such as cardboard boxes and packaging bags. It has a wide range of uses.

Equipment advantages

1. Strong conveying capacity.

2. The transportation is smooth, and there is no relative movement between the material and the conveyor belt, which can avoid damage to the material.

3. Simple structure and easy maintenance.

4. Low energy consumption, low noise, and environmentally friendly.

5. The feeder runs smoothly, especially our factory's production feeder, which meets the requirements of large feeding volumes and is favored by users.

The arch breaker device is a major breakthrough in the design and production of our factory, which can effectively relieve the pressure at the warehouse opening and prevent the material from being trapped. The 6+1 type skirt edge is formed by one-time vulcanization, with 6 layers of nylon yarn and 1 layer of ultra-fine diamond woven steel wire mesh imported from Japan. It has strong tensile strength, friction resistance, and anti combustion ability. The external skirt edge not only prevents the leakage of fine powder from the material, but also prevents the overflow of moisture in the material. Providing up to thousands of tons of material per hour greatly meets the needs of modern production and creates significant economic benefits for customers.

| model | powerKW | voltageV | environment | Feed quantity | Adjustment method for feeding quantity | Installation size | Maximum external dimensions for transportation |

| t/h | mm | mm | |||||

| PDG/4/P/S-1 | 4 | 380/660 | Common | 200-1000 | Manual infinitely variable transmission | K-3 | long2825 |

| LDG/4/P/B-1 | Variable frequency infinite variable speed | wide1430 | |||||

| PDG/4/P/S-1 | Explosion proof type | Manual infinitely variable transmission | tall1705 | ||||

| LDG/4/P/B-1 | Variable frequency infinite variable speed | ||||||

| PDG/5/P/S-1 | 5.5 | Common | 520-2600 | Manual infinitely variable transmission | K-4 | long3250 | |

| LDG/5/P/B-1 | Variable frequency infinite variable speed | wide1630 | |||||

| PDG/5/F/S-1 | Explosion proof type | Manual infinitely variable transmission | tall1850 | ||||

| LDG/5/F/B-1 | Variable frequency infinite variable speed |

Our advantages

Related products