威达机械

集研发、设计、生产、销售一站式服务

One stop service for research and development, design, production, and sales 在线咨询 >

quick response

Free customization

Worry free service

PRODUCT DETAILS

working principle:

The ZSL series large cold ore vibrating screen belongs to the dual axis linear vibrating screen, which is driven by two electric motors to drive the exciter outside the transmission shaft for reverse self synchronous rotation, causing the screen box to produce a large amplitude linear vibration. The motor does not participate in vibration. This vibrating screen has the advantages of high production capacity, reliable operation, convenient amplitude adjustment, and low dynamic load transmitted to the foundation. It has been widely used in industrial sectors such as metallurgy, mining, coal, and ports, mainly for temperatures below 150 ° C; Cold sintered ore grading operation.

Structural features:

This series of vibrating screens consists of a screen box, exciter, supporting spring, isolation frame, secondary isolation spring, motor and its bracket, etc.

The screen frame component consists of a screen frame, a sieve plate, and a fastening device. The side plate of the screen frame is made of high-quality steel plate, and the connection between the side plate, reinforcement plate, crossbeam, and exciter chassis is made of high-strength bolts and self-locking nuts or ring groove rivets, which are firm and reliable.

The exciter is usually installed on both side plates of the upper part of the screen frame. Made into an upper vibration structure, the exciter can also be arranged on the upper part of the screen frame and connected with a universal joint. The exciter is sealed with a labyrinth ring and lubricated with dry oil. This series of cold frame screen plates adopts wear-resistant alloy steel or stainless steel screen plates, which have the characteristics of no deformation and long service life.

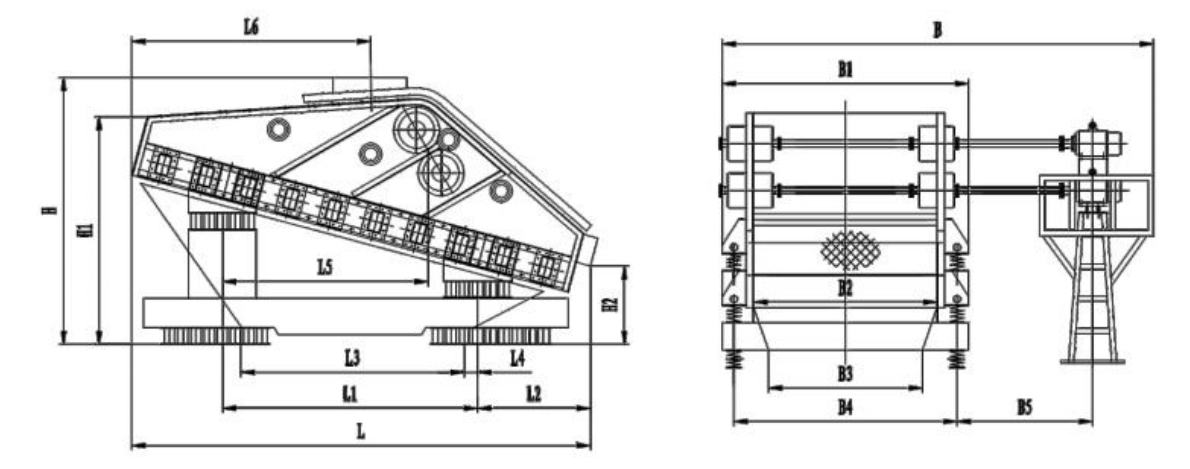

Outline diagram:

| model | Feed particle size | Processing capacity | motor | ||

| model | power | voltage | |||

| ZSL1860 | <200 | 100-250 | Y200L-8 | 2*15 | 380 |

| ZSL2060 | <200 | 200-300 | Y200L-8 | 2*15 | |

| ZSL2575 | <200 | 250-400 | Y225S-8 | 2*18.5 | |

| ZSL3070 | <300 | 350-500 | Y225M-8 | 2*22 | |

| ZSL3175 | <300 | 450-600 | Y225M-8 | 2*22 | |

| ZSL3090 | <300 | 550-700 | Y280S-8 | 2*37 | |

Our advantages

Related products