威达机械

集研发、设计、生产、销售一站式服务

One stop service for research and development, design, production, and sales 在线咨询 >

quick response

Free customization

Worry free service

PRODUCT DETAILS

Product Overview:

Compared with traditional screw conveyors with shafts, shaftless screw conveyors have the following outstanding advantages due to the adoption of a centerless shaft design and the use of a flexible integral steel screw to push materials: strong resistance to entanglement. The shaftless screw conveyor is a new type of screw conveyor independently developed by our company based on the actual situation where LS and GX types of screw conveyors are used in industries such as building materials, chemical, environmental protection, power, medicine, metallurgy, and food to transport materials with high abrasion resistance, high viscosity, easy agglomeration, and easy entanglement of materials, resulting in material blockage and damaged suspension bearings that prevent the screw machine from working properly. This product is suitable for continuous and uniform conveying of loose, viscous, and easily entangled materials. The maximum temperature of the conveyed material can reach 100 ℃, and the maximum inclination angle is less than 45 °.

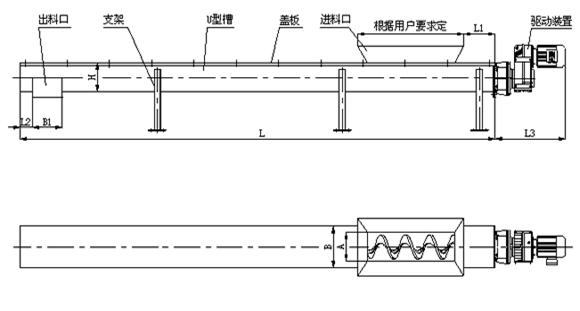

Structure and working principle:

The shaftless screw conveyor is mainly composed of a driving device, head assembly, casing, shaftless screw body, groove lining plate, feeding port, discharging port, machine cover (when needed), base, etc.

Drive device: Adopting cycloidal pinwheel reducer or shaft mounted hard tooth surface gear reducer, the drive device should be designed to be located at the discharge port end as much as possible, so that the spiral body is in a tensile state during operation. The head is equipped with thrust bearings that can withstand the axial force generated during material transportation.

Chassis: The chassis is U-shaped or O-shaped, with a rainproof cover on the top, made of stainless steel, carbon steel, or fiberglass.

Axial free spiral body: made of stainless steel or carbon steel.

Tank lining plate: made of wear-resistant plastic plate, rubber plate, cast stone plate, etc. Inlet and outlet: There are two types: square and circular. Generally, the form of inlet and outlet is determined by the user.

Main features:

The shaftless screw conveyor can transport materials that traditional shaft screw conveyors and belt conveyors cannot or are difficult to transport, such as granular and powdery materials, wet and paste materials, semi fluid and viscous materials, materials that are prone to entanglement and blockage, and materials with special hygiene requirements. The performance characteristics of the shaftless screw conveyor are: compared with the traditional shaft screw conveyor, the shaftless screw conveyor has outstanding advantages and good environmental performance due to the use of a non central shaft design and the use of a flexible integral steel screw to push materials. Compared to screw conveyors with shafts, the weight and cost will be significantly reduced.

1. Good environmental performance. The use of fully enclosed and easy to clean spiral surfaces ensures that the conveyed material is not contaminated and will not leak during transportation.

2. The conveying capacity is large, which is 1.5 times that of a screw conveyor with a shaft of the same diameter.

3. Large turning distance, low energy consumption, and unobstructed discharge port.

4. Long conveying distance, single machine conveying length can reach 60-70m.

5. Compact structure, space saving, beautiful appearance, easy operation, economical and durable.

Technical parameters:

| WLS type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Spiral diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| rotational speed(r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Conveying capacityQ=0.33 ( m3/h ) | 2.2 | 7,6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| Power Pd l=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5,1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd l=30m(KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15,3 | 25.9 | 36 | 48 | 73.3 |

| rotational speed (r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Conveying capacity Q=0.33 ( m3/h ) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd l=10m(KW) | 1 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd l=30m(KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42,2 | 49.5 |

| rotational speed (r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Conveying capacity Q=0.33 ( m3/h > | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd l=10m(KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| Power Pd l=30m(KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5,4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| rotational speed (r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Conveying capacity Q=0.33 ( m3/h > | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73 | 99.3 | 139 | 199 |

| Power Pd l=10m(KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7,7 | 11 |

| Power Pd l=30m(KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

Our advantages

Related products