威达机械

集研发、设计、生产、销售一站式服务

One stop service for research and development, design, production, and sales 在线咨询 >

quick response

Free customization

Worry free service

PRODUCT DETAILS

Product Overview:

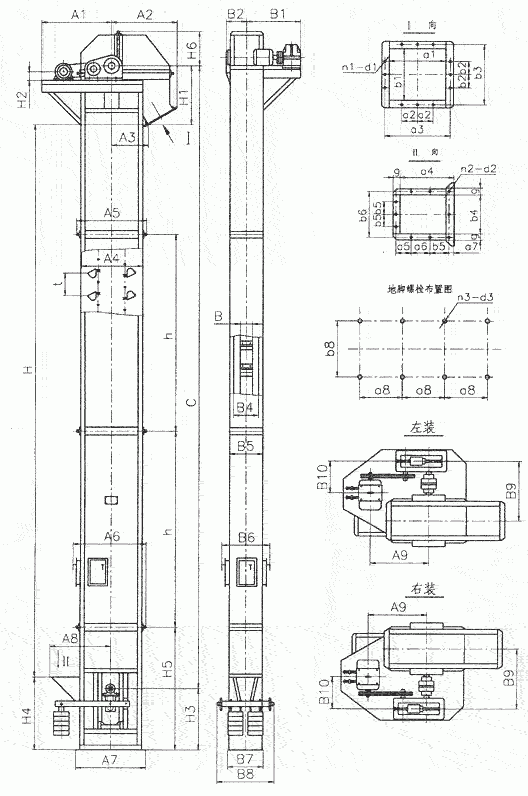

The TH type bucket elevator is a new generation elevator that is equivalent to the international standard ISO5050-81. Suitable for vertical transportation of low abrasive materials such as grain, coal, and cement in powder, granular, and small block forms. Crushed ore, etc., with a material stacking density not exceeding 1.5t/m ³; The material temperature shall not exceed 250 ℃.

Structural characteristics and working principle:

The TH series bucket elevator consists of a tail part, a middle groove body, a head part, a bucket chain component, and a drive device. Fully enclosed casing ensures no material leakage during equipment operation. The lifting conveyor chain adopts stamped plate type chain, which can be arranged in single chain and double chain types. The head is equipped with a backstop for reliable backstop. The inlet and outlet of the equipment, as well as the lifting height, can be flexibly designed and arranged according to the process requirements. TH type is a circular chain bucket elevator that uses mixed or gravity unloading and digging loading. High quality alloy steel high circular chain is used for traction components. The central casing is divided into two forms: single channel and double channel. The internal heavy hammer box is automatically tensioned with constant force. The sprocket adopts a replaceable wheel rim combination structure. Long service life and easy replacement of wheel rims. The lower part adopts a gravity automatic tensioning device, which can maintain a constant tension force, avoid slipping or chain detachment. At the same time, the hopper has a certain tolerance when encountering jamming caused by accidental factors, which can effectively protect the lower shaft and other components. This bucket elevator is suitable for conveying powdery, granular, and small block shaped bottom grinding materials with a bulk density of less than 1.5t/m3 that are easy to remove. Such as coal, cement, gravel, sand, fertilizers, grains, etc. TH type bucket elevator is used for vertical conveying of various bulk materials. Suitable for conveying powdery, granular, and small block materials, with material temperatures below 250 ℃.

Main features:

1. Easy maintenance and long lifespan.

2. The casing steel plate is thickened and has good rigidity.

The maximum temperature for conveying materials can reach 250 ℃.

4. The middle section casing has two forms: single channel and dual channel.

5. Elevate the height to ensure smooth and reliable operation, low noise, and easy maintenance.

6. The improved model increases the conveying capacity by more than 30% compared to ordinary models.

7. The hoist ring chain is forged from low-alloy steel and undergoes carburizing and quenching treatment, possessing extremely high tensile strength and wear resistance.

| model | TH315 | TH400 | TH500 | TH600 | ||||

| Type of hopper | ZH | SH | ZH | SH | ZH | SH | ZH | SH |

| Conveying capacity(m3/h) | 35 | 59 | 58 | 94 | 73 | 118 | 114 | 185 |

| bucket capacity(L) | 3.75 | 6 | 5.9 | 9.5 | 9.3 | 15 | 14.6 | 23.6 |

| pitch of buckets(mm) | 512 | 688 | ||||||

| Round steel diameter x pitch | Φ18x64 | Φ12.1x86 | ||||||

| Single chain strength component | ≥ 320 | ≥ 480 | ||||||

| Traction weight per unit length (kg/m) | 25.64 | 26.57 | 31 | 31.9 | 41.5 | 44.2 | 49 | 52.3 |

| Drive sprocket speed (RPM) | 42.5 | 37.6 | 35.8 | 31.8 | ||||

| Maximum particle size of conveyed materials(mm) | 35 | 40 | 50 | 60 | ||||

| Maximum particle size of conveyed materials(m/t) | 1.4 | 1.5 | ||||||

| pour | ZH Representative of Zhongshen Dou | SH Representing Deep Struggle |

Our advantages

Related products