威达机械

集研发、设计、生产、销售一站式服务

One stop service for research and development, design, production, and sales 在线咨询 >

quick response

Free customization

Worry free service

PRODUCT DETAILS

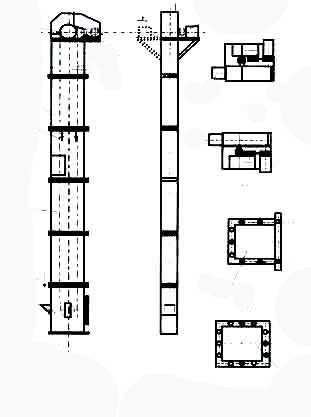

Structural characteristics and working principle: The TD series bucket elevator consists of a tail part, a middle groove body, a head part, a bucket chain component, and a driving device. Fully enclosed casing ensures no material leakage during equipment operation. The lifting conveyor belt is made of rubber belt, with an external bucket layout and a head equipped with a reliable backstop. The inlet and outlet of the equipment, as well as the lifting height, can be flexibly designed and arranged according to the process requirements.

The material is uniformly introduced into the hopper installed and fixed on the lifting tape for continuous closed operation through the equipment inlet, and lifted from the tail inlet to the head outlet for discharge, achieving single point feeding, single point centrifugal or mixed discharge. The lifting conveyor belt adopts a screw adjustment device to adjust the tightness of the conveyor belt, ensuring that it always maintains a moderate tension state during operation and keeps the equipment in a stable operating state.

Applicable materials:

TD and D-type tape bucket elevators are suitable for vertically conveying powdery, granular, and small bulk materials with low grinding properties, such as grains, coal cement, crushed ores, etc. The maximum lifting height is 40m. Its characteristics are: simple structure, smooth operation, digging type loading, centrifugal unloading, and material temperature not exceeding 60 ℃. TD type is designed and manufactured according to JB3926-85 "Vertical Bucket Elevator" standard. Compared with traditional D-type bucket elevators, it has high conveying efficiency and multiple hopper types, and should be preferred.

The advantages of this elevator are:

1. The TD type has a large conveying capacity, and compared to the D type with the same bucket width, the conveying capacity is nearly doubled. 2. The traction parts use high-strength rubber conveyor belts with high tensile strength and long service life. 3. The overall structure is simple, easy to install, and convenient for adjustment, maintenance, and upkeep.

4. The traction component is a low-alloy high-strength circular ring chain, which, after appropriate heat treatment, has high tensile strength and wear resistance, and a long service life. This hoist is used for centrifugal or mixed unloading and extraction loading, and is suitable for conveying low abrasive materials with a bulk density of no more than 1.5t/m3, including powder, granular, and small pieces. The temperature of the materials should not exceed 60 degrees. This series of bucket elevators is equipped with four types of hoppers: Q-type (shallow hopper), H-type (arc bottom hopper), zh type (medium deep hopper), and sh type (deep hopper), which respectively transport various materials. Users can choose the appropriate hopper according to the characteristics of the materials.

Installation dimensions of TD-D bucket elevator:

Technical parameter table of TD-D bucket elevator:

| model | TD160 | TD250 | TD315 | TD400 | ||||||||||||

| Form of hopper | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd |

| Conveying capacity(m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Dou Kuan(mm) | 160 | 250 | 315 | 400 | ||||||||||||

| bucket capacity(L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3 | 4.6 | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| pitch of buckets(mm) | 280 | 350 | 360 | 450 | 400 | 500 | 480 | 560 | ||||||||

| bandwidth(mm) | 200 | 300 | 400 | 500 | ||||||||||||

| Dou Speed(m/s) | 1.4 | 1.6 | 1.6 | 1.8 | ||||||||||||

| Large chunks of material quantity(mm) | 25 | 35 | 45 | 55 | ||||||||||||

| model | TD500 | TD630 | TD160 | TD250 | TD350 | TD450 | ||||||||||

| Form of hopper | Q | h | zD | Sd | h | zD | Sd | Q | S | Q | S | Q | S | Q | S | |

| Conveying capacity(m3/h) | 38 | 70 | 58 | 92 | 85 | 89 | 142 | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 | |

| Dou Kuan(mm) | 500 | 630 | 160 | 250 | 350 | 450 | ||||||||||

| bucket capacity(L) | 4.8 | 9 | 9.3 | 15 | 14 | 14.6 | 23.5 | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 | |

| pitch of buckets(mm) | 500 | 625 | 710 | 300 | 400 | 500 | 640 | |||||||||

| bandwidth(mm) | 600 | 700 | 200 | 300 | 400 | 500 | ||||||||||

| Dou Speed(m/s) | 1.8 | 2 | 1 | 1.25 | 1.25 | 1.25 | ||||||||||

| Large chunks of material quantity(mm) | 60 | 70 | 25 | 35 | 45 | 55 |

explain:

1. The bucket capacity in the table is calculated, and the conveying capacity is calculated based on a filling coefficient of 0.6.

2. The purpose of the hopper of the bucket elevator is:

Shallow hopper: Conveys materials that are damp, prone to clumping, and difficult to throw out. Such as wet sand, wet coal, etc.

Deep hopper: Conveys dry, loose, and easily thrown materials. Such as cement, coal, gravel, etc.

Our advantages

Related products