威达机械

集研发、设计、生产、销售一站式服务

One stop service for research and development, design, production, and sales 在线咨询 >

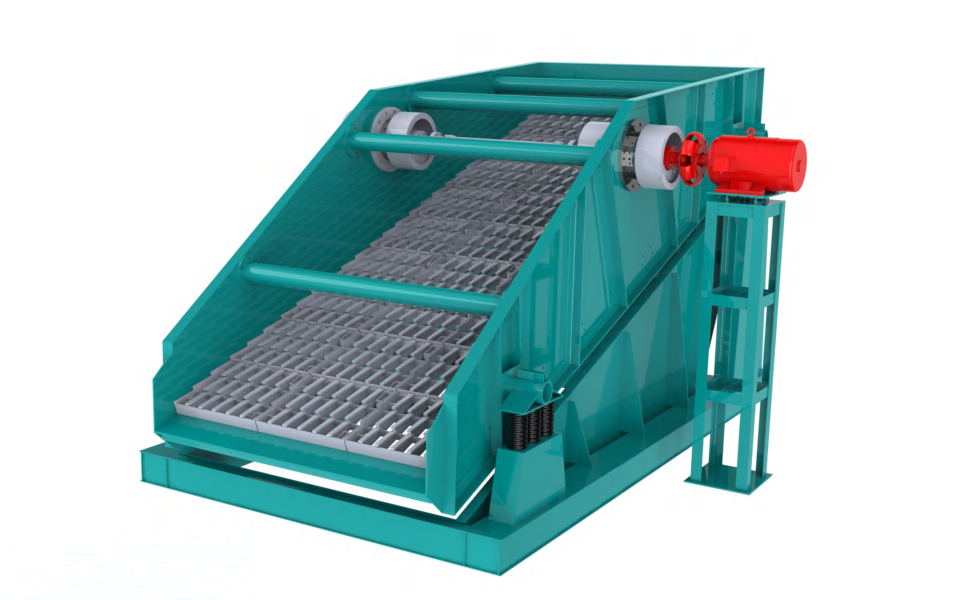

Circular vibrating screen is actually a method of using the centrifugal force generated by the rotation of eccentric blocks in a vibrator to force continuous circular or approximately circular motion of parts such as the screen box and vibrator. The material undergoes continuous throwing motion on the inclined screen surface with the sieve box; Layering occurs when thrown up; When falling, the particles will pass through the sieve.

Linear vibrating screen is a type of screen that uses a vibrating motor to stimulate the lifting force, causing the material to be thrown up on the screen and move forward in a straight line. The material is evenly fed into the feed inlet of the screening machine from the feeder, and through multiple layers of screens, several specifications of sieved material and undersized material are produced and discharged from their respective outlets. It is widely used in the mining industry.

From the literal meaning, it can be seen that the circular vibrating screen and the linear screen are different in appearance. So, are there any other differences besides this? Let me introduce you to the 5 main differences between circular vibrating screens and linear screens!

Difference 1: Different materials

The materials used for the production of linear vibrating screens are mostly lightweight or stainless steel plates.

The circular vibrating screen is made of thick materials, and the box is made of manganese steel, which can resist the impact force of materials during the screening process.

Difference 2: Different exterior structures

The linear vibrating screen can adopt a fully enclosed structure, without dust spillage, which is more conducive to protecting the environment.

The exciter of the circular vibrating screen is arranged above the center of gravity of the screen box, and the material can quickly disperse. The processing capacity per unit time is higher than that of the linear vibrating screen.

Difference 3: Different application fields

Linear sieve mainly screens fine particles, materials with low hardness and light density, mainly in the form of fine particles, dry powder or micro powder materials. It is usually widely used in the chemical, building materials, food and pharmaceutical industries.

Circular vibrating screen is mainly used to screen materials with large particles, high specific gravity, and high hardness, and is widely used in mining industries such as coal, mining, and quarrying. In addition, some difficult to screen materials can also be screened using a circular vibrating screen.

Difference 4: Different motion trajectories

The material on the linear sieve moves forward in a straight line.

The material on the circular vibrating screen undergoes circular motion.

Difference 5: Different installation angles

The inclination angle of the screen surface of the linear vibrating screen is relatively small in production, and the height of the screen is reduced, which is convenient for production.

Circular vibrating screens usually have an installation inclination angle of 15-20 degrees, which changes the speed of material movement along the screen surface and improves its screening efficiency.

In summary, we can find that there are differences between circular vibrating screens and linear screens in five aspects: material, external structure, application field, motion trajectory, and installation angle. Therefore, when using or purchasing both, it is important to distinguish which type of vibrating screen it is.